| Edition 27 - December 2015 |

|

Click Here to View as Web Page |

|

|

|

|

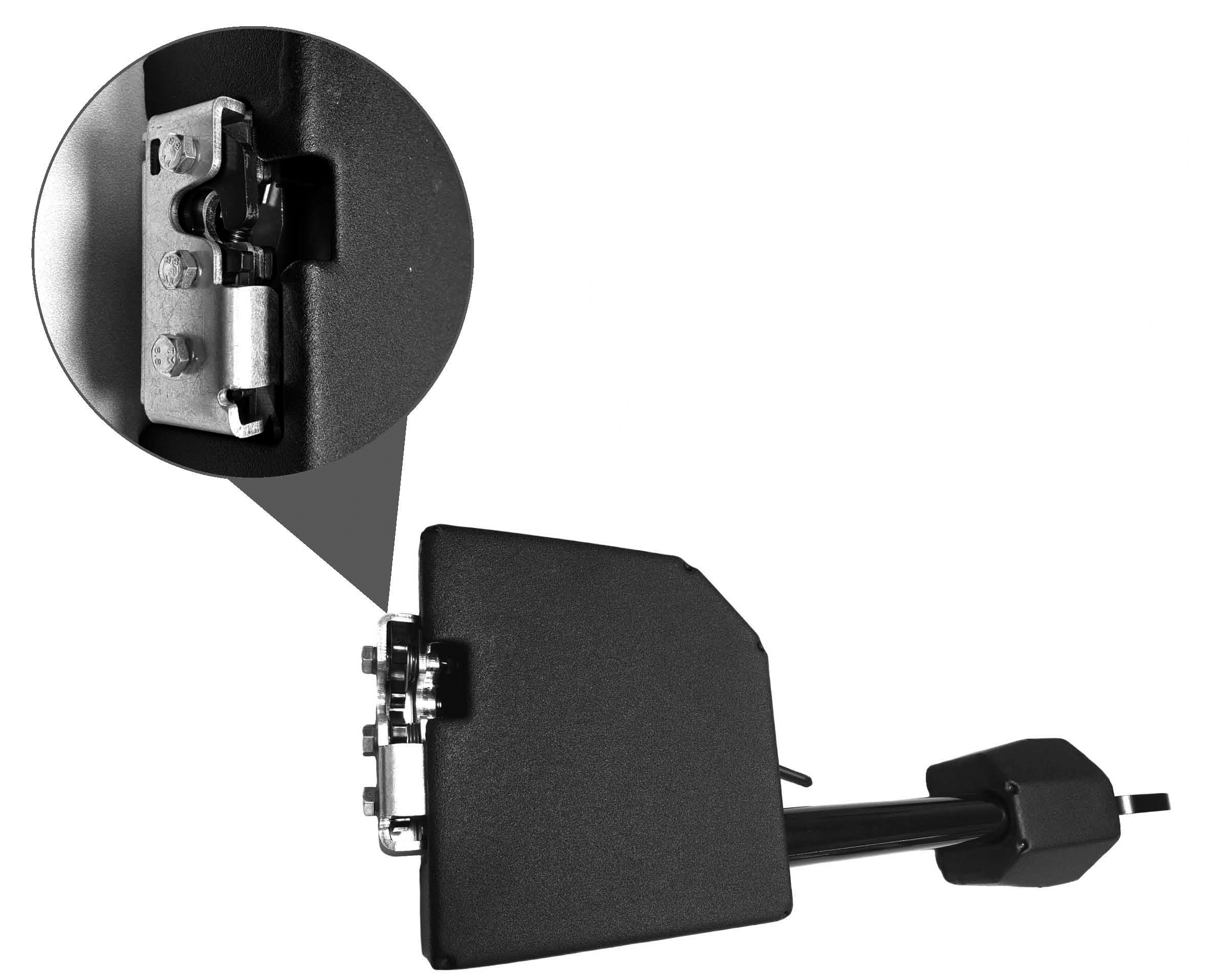

100-5020 TriGuard Heavy Duty Door Module - V2  This heavy duty, pre-engineered door hardware module provides automotive-like functionality and style in a low profile, easy to install one-piece module. Featuring TriMark’s 050-1600 Heavy Duty Latch, this robust product allows for power locking and is compliant to FMVSS 206 strength requirements. Other product details include:

System kits are available and include power lock actuators and electronic accessories including custom wiring harnesses, relays, switches, door contacts, actuators and mounting hardware to provide a comprehensive electro-mechanical access solution. |

|

bauma2016 April 11 - 17 Munich, Germany |

EDITOR'S NOTE: If you would like to send a copy of this e-newsletter to a friend, colleague or associate, the Send to a Friend link at the bottom of this newsletter is a convenient method for providing them with their own personal copy.

|

|

It’s no secret that the world is getting “smaller” from a business standpoint. We’ve commented on many occasions in this newsletter about how TriMark is being challenged by our customers to assist them in addressing their global customer and regulatory requirements. TriMark customers are looking for every competitive advantage they can get and are increasingly asking for our assistance in seeking out and executing those strategic advantages. In September, TriMark displayed at the DSEi which is a world leading defense and security event held in London. The event attracted record numbers of high-profile stakeholders affiliated with the defense and security sectors. To give you some idea of just how “global” this event has become, consider these facts:

We are also seeing the same type of international growth in other events where we participate such as bauma Munich, CONEXPO, and APTA to name just three. The point here is that TriMark continues to develop and design platforms and products which allow our customers to utilize “off-the-shelf” Access Solutions. Here in Iowa we’ve experienced record-setting bushels per acre corn and soybean harvest. Many Iowa towns have massive piles of corn waiting to be transported for processing. While the massive harvest creates issues with farmers forcing low commodity prices, we also have to say that we are truly fortunate to be able to provide such a bountiful harvest knowing that the value-added products produced will provide food and nourishment for a growing world population growing increasingly dependent on our robust productivity. To all of our friends please know how fortunate we feel to have you as a part of the TriMark family and we want to wish you all a wonderful holiday season. The TriMark Management Team |

| |

|

| TriMark showcased its Armored Vehicle products at DSEi - the world leading defense and security event - September in London. TriMark's new 100-5020 Heavy Duty Door Module - V2 was the major focal point. In addition, TriMark featured its TriGuard line of heavy duty latches, linkages, handles and door modules specifically developed for heavy duty armored vehicle applications.

TriGuard Product Line – A Systems Approach  Offering security, reliability and modularity, the TriGuard line of TriMark's heavy duty latches, linkages, handles and door modules are specifically developed for heavy duty armored vehicle applications. These robust door product/systems simplify vehicle/door mounting with reduced attachment points and door assembly. Already proven in several blast tests the 050-0850 heavy duty latch/striker survives in punishing environments and provides rotor/cam assist to heavy doors/armor and hinges helping to compensate for door sag. These products can be used on retrofit, up-armor applications or new surface mount vehicle construction and can be purchased as separate products or complete one-piece modules ready for installation. In addition, the TriGuard line of products is fully compatible and offers flexibility and adaptability to suit your specific application needs. Offering security, reliability and modularity, the TriGuard line of TriMark's heavy duty latches, linkages, handles and door modules are specifically developed for heavy duty armored vehicle applications. These robust door product/systems simplify vehicle/door mounting with reduced attachment points and door assembly. Already proven in several blast tests the 050-0850 heavy duty latch/striker survives in punishing environments and provides rotor/cam assist to heavy doors/armor and hinges helping to compensate for door sag. These products can be used on retrofit, up-armor applications or new surface mount vehicle construction and can be purchased as separate products or complete one-piece modules ready for installation. In addition, the TriGuard line of products is fully compatible and offers flexibility and adaptability to suit your specific application needs.

TriMark Website Update TriMark completed an update to the section of its website devoted to the Armored Vehicle market.

This section of the website includes a comprehensive listing of products and components developed for this demanding market including the TriGuard line of products as well as COMMANDoor powered door system. |

|

TriMark engineers are a very talented group! The TriMark Engineering Team is comprised of both mechanical and electrical engineers. More and more of the access challenges we tackle involve the combining of both mechanical and electrical skill sets into “mechatronic” access solutions. This integration continues to pay dividends for TriMark customers as we have evolved into a recognized leader in this area of expertise. So now you know about the skills of the engineering team so now let’s take a closer look at how these tools and skills are brought together to solve problems and tackle customer challenges. Off-the-Shelf Solutions are Just One Way Application Engineering Benefits Our Customers While we know and understand each market may require its own unique product solutions – RV entrance doors are not the same as construction equipment personnel doors, for example, TriMark always checks the full complement of current product platforms to determine if we have a product solution that could be readily available or easily modified. Growing the Solutions Base We are always expanding our Off-the-Shelf product solutions base; so many times we can provide an access hardware solution without having to “reinvent the wheel.” We’ve developed a simple graphic which helps us explain to customers how TriMark approaches the Product Development Process access options and solutions.  Application Engineering If standard Off-The-Shelf products do not provide the solution for your immediate needs, we have two additional product options available or TriMark can develop an all new design that’s engineered specifically for your requirements and application. Many times we have components available that can be assembled in a different Bill of Material that does not require anything further than a part number release. In addition, we can modify existing products based on the application needs, thereby shortening the development cycle which our customers appreciate. In its most basic definition, Application Engineering means that we are applying all kinds of technology to tackle a customer challenge. For example, a TriMark customer may come to us and say, “this is what I want to do" and we then figure out what kind of product and technology we will need to employ to solve that challenge. The truth is TriMark manufacturing will also want to be able to manufacture a product in as easy and efficient manner as possible, balancing the product vs. volume requirements. At the same time, the TriMark customer wants and expects the best product to satisfy their requirements. It’s the job of the TriMark application engineer to see that both objectives are accomplished. TriMark engineers work closely with our customers early in the development process in order to select and/or design the best access hardware product thereby avoiding unnecessary product and engineering expense. Bottom Line - TriMark Can Offer a Full Range of Platform and Product Solutions – Just Ask Us! |

|

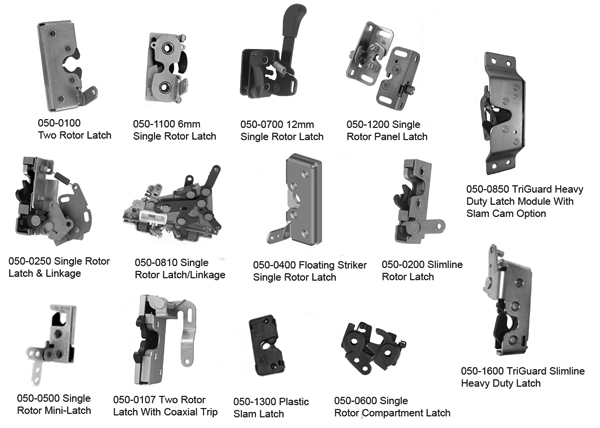

You may already know that TriMark has produced over 33 MILLION Rotary Latches making it the global leader in Rotary latch solutions. And while this number is very impressive in and of itself, the TriMark rotary latch story goes well beyond mere numbers. The range and breadth of the Rotary Latch product line has been built on years of careful engineering evolution as well as successful customer experiences with the full range of latch options. Leading the industry in reliability and durability, products range from basic stand-alone designs to integrated linkages for both FMVSS 206 and non-206 applications. Offering a broad selection of rotary latch sizes, versions, features and options to meet virtually any application, all TriMark rotary latches feature the highest levels of quality, security and strength. In addition, all TriMark Rotary Latch products are covered by TriMark’s comprehensive worldwide warranty, giving you confidence and peace of mind. Rotary Latches 101 When you’ve made over 33 million rotary latches it is easy to forget that, while we at TriMark may be intimately familiar with the complete product offering, we need to be constantly aware that our customers also need to be “in the loop” about our rotary latch platforms and sub-platforms. We thought that it might be a good idea to re-visit the basic configuration options for our rotary latches (single and two-rotor latches) as well as a more comprehensive look at the full range of available latches. Two Rotor TriMark's proven two rotor latches leads the industry in reliability and durability. Products range from basic stand-alone designs to integrated linkages for both FMVSS 206 and non-206 applications. Available in a wide variety of versions and options, they offer robust latching functions in several cost effective designs. Single Rotor TriMark's extensive single rotor latch products range from compact compartment latches to FMVSS 206 compliant latches. Available in a wide variety of versions and options, they offer reliable latching functions in several low cost and compact designs. Many rotary latches are produced as stand-alone products as well as being integrated into other products such as paddle handles and door modules. Integration of electronics is also available, providing power locking, power release and door open sensing providing a complete mechatronic solution. In addition, accessories such as striker bolts, cage nuts, linkages, rods, cables and clips are available to provide a comprehensive access solution.

Reinforcing the broad spectrum of applications, TriMark is currently producing about 2 million units per year for a variety of customers and industries:

Let TriMark Help You! Are you having trouble getting the rotary latch solution you need? As the global leader in providing rotary latch solutions, TriMark will have the answer that is right for you. Whether it is one of our proven and time-tested off- the-shelf platforms/products or a fully-custom solution requiring the full skills and expertise of TriMark’s product development experts, we know you will be more than pleased with the TriMark access solution designed just for YOU! |

|

TriMark Corporation 500 Bailey Avenue PO Box 350 New Hampton, IA 50659 Tollfree: 1-800-447-0343 Phone: 1-641-394-3188 Fax: 1-641-394-2392 Email: tips@trimarkcorp.com Visit us on the web at www.trimarkcorp.com This e-newsletter is a service of TriMark Corp. and is produced by The Bearings Group |